Through our teaching and consulting we provide a very holistic approach to organisational improvement and sustainable organisational excellence. Our thinking has been influenced by the likes of pioneers in the field like Edwards Deming.

A set of key principles or premises underpin our thinking and work. They are based on what Deming called “Profound Knowledge”. In future Blogs I will outline these principles. In essence though, our argument is that Sustainable High Performance for an organisation stems from the application of these key principles and practices that underpin Business Excellence or Improvement.

The combination of these Leadership modelled practices creates the essence of strategic thinking and execution for any organisation. This is what I want to outline as a starting point to the subject of the science of improvement. In our courses and engagements we always set the scene with these ideas as a context to explain why we cover what we do. It is surprising how often people indicate that they do not observe these practices in operation in their workplaces and in their experience. They tell stories that illustrate the lack of these principles in play.

Let me outline the high level ideas and then invite a response.

Fit to the Market

For Deming and other Pioneers in the field of organisational excellence, ‘Outside In Thinking’ was a starting point for designing a high performing organisation. Understanding the market(s) being served now and into the future created the purpose to the design. What does this mean?

In the first instance it means understanding needs and experiences desired by the groups of customers served by the organisation. At the most strategic level this would involve understanding the broader environment surrounding these customers including the competitive environment or the regulatory environment or the internal organisational environment and so on. In the end a choice would be made to play in a ‘particular game’ – serve a group of customers – a market and seek to deliver their desired experiences better than others or at least be among the best. How can this be achieved without clearly understanding the market you intend to serve and how well others (if they exist) are doing it now. So having a strong Market or Customer Focus involves defining the market in terms of who they are and what they want – the crux of any useful ‘Value Proposition’.

Defining needs and requirements has got much more substantive in terms of understanding the Total Customer or Market Experience (TCE) – from Awareness through Purchasing to Using to Service etc. For a given industry and market this cycle of experiences would be unique. Experiences that are important and drive loyalty had better be delivered well.

Strategy is further defined by selecting which experiences will be delivered differently or extended to distinguish the organisation from others. The belief here is that if this is done well then customers will be attracted and held!! There are various approaches to understanding the Total Customer Experience of markets. So for Deming and others a key aspect of sustainable high performance was delivering the experiences desired by the market (the desired quality) at a price that suited the market.

Strategy is further defined by selecting which experiences will be delivered differently or extended to distinguish the organisation from others. The belief here is that if this is done well then customers will be attracted and held!! There are various approaches to understanding the Total Customer Experience of markets. So for Deming and others a key aspect of sustainable high performance was delivering the experiences desired by the market (the desired quality) at a price that suited the market.

So one responsibility for the exercise of Leadership is to make clear to all the ‘Game Plan’ in terms of the target Total Experience that needs to be delivered. Notice I have not used terms like needs or requirements or specifications. Understanding of this element of Deming’s thinking has evolved a lot in terms of work in such areas as customer experience design – a topic for another time!!

Design the Value Stream to FIT the Market TCE

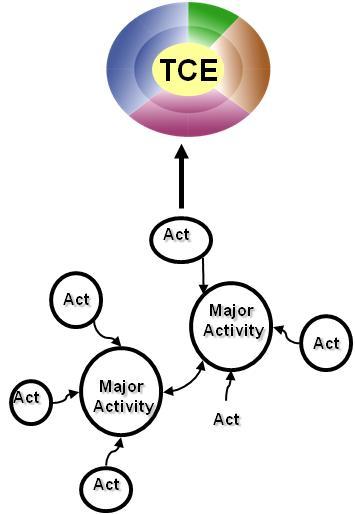

However, central to strategic thinking for Deming was ‘Systems Thinking’. Here the responsibility of Leaders as ‘Architects’ of the organisation was to call out the critical design of the sequence of interrelated activities that used the raw inputs and turned them into the end benefits and experiences for the customers in the market – ‘the end to end Value Stream’.

However, central to strategic thinking for Deming was ‘Systems Thinking’. Here the responsibility of Leaders as ‘Architects’ of the organisation was to call out the critical design of the sequence of interrelated activities that used the raw inputs and turned them into the end benefits and experiences for the customers in the market – ‘the end to end Value Stream’.

The thinking of Leaders should be bent to calling out the critical nature or performance characteristic of parts of the Value Stream (processes). This would be based on understanding what drives or delivers the key or important desired experiences. Even further (and characteristic of Systems Thinking) the key interdependencies between processes (functional groups) would be called out to ensure the alignment of all elements of the value stream towards cooperation and collaboration in delivering desired experiences. In other words leaders would not leave it to chance that different groups would be in synch! But would clearly call it out which would influence organisational activity from planning and communication to goaling and performance measurement. In essence strategy here is calling out how the whole should function and the critical interdependencies that need to be achieved – the strategic themes!!

Imagine a sporting team where individuals or subgroups interpreted what they had to do on the field of play or during a competition independently of one another!

All groups in the Value Stream would have access to ‘The blueprint’ – engaging with it and using it to guide alignment and cross teamwork. Leaders would work hard to drive execution to the design and to ensure organisational elements don’t drag teams away from an aligned and integrated strategy.

Sustainable High Performance comes from the pursuit of this philosophy over time.

The feedback from many people in our classes has been that this form of strategic thinking is not commonly demonstrated within their organisations.

Execution to the Design

Nice to have a design – to have strategic thinking clearly laid out in simple terms for all to see. However, Execution to the design is the rub!

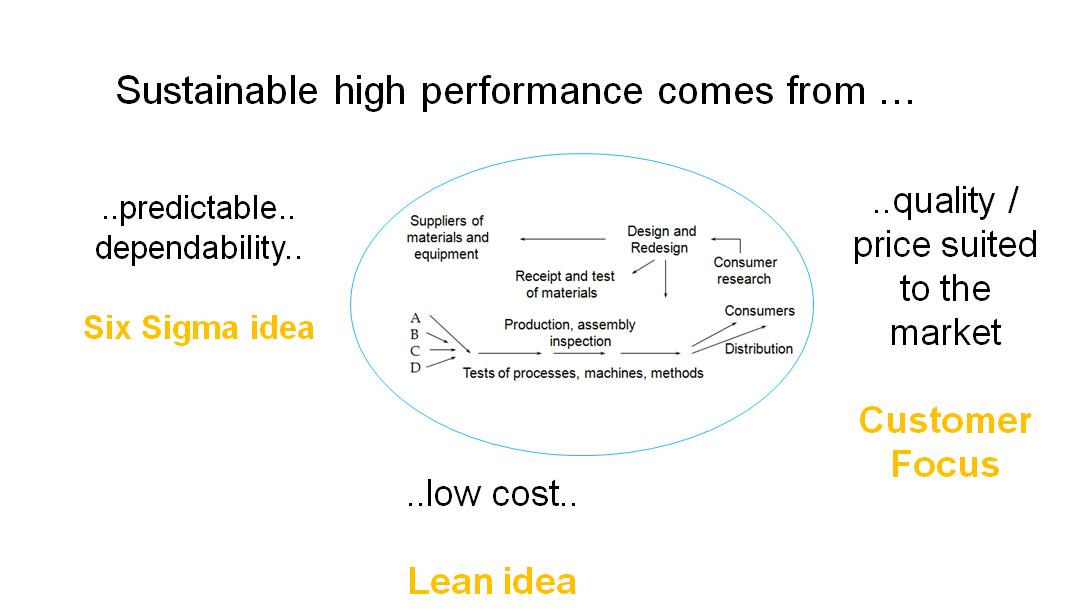

For Deming, a market needed to experience what is delivered in a ‘dependable and predictable’ fashion. It’s unlikely that you will hold or attract customers if you have a reputation for not delivering what they want reliably. Herein lies the concept of ‘Process Sigma or Six Sigma’ again a topic for another time – ‘Understanding Variation’.

Further, Deming argued that customers want to pay a price that suits them and so the organisation needs to be operating with as little waste as possible so that costs are as low as possible – the ‘Lean’ idea. Such an organisation would be in a much better position to set a price!!

Long before Lean and Six Sigma became ‘Buzz Words’ the concepts were part of Deming’s philosophy!!

Given Deming’s thinking, Sustainable High Performance is driven by Designing the Value Stream to Fit the Market and then Executing the Design. Leadership has a key responsibility to create the architecture and then enable it to happen – easier said than done!! But then that’s why they are in Leadership roles!!

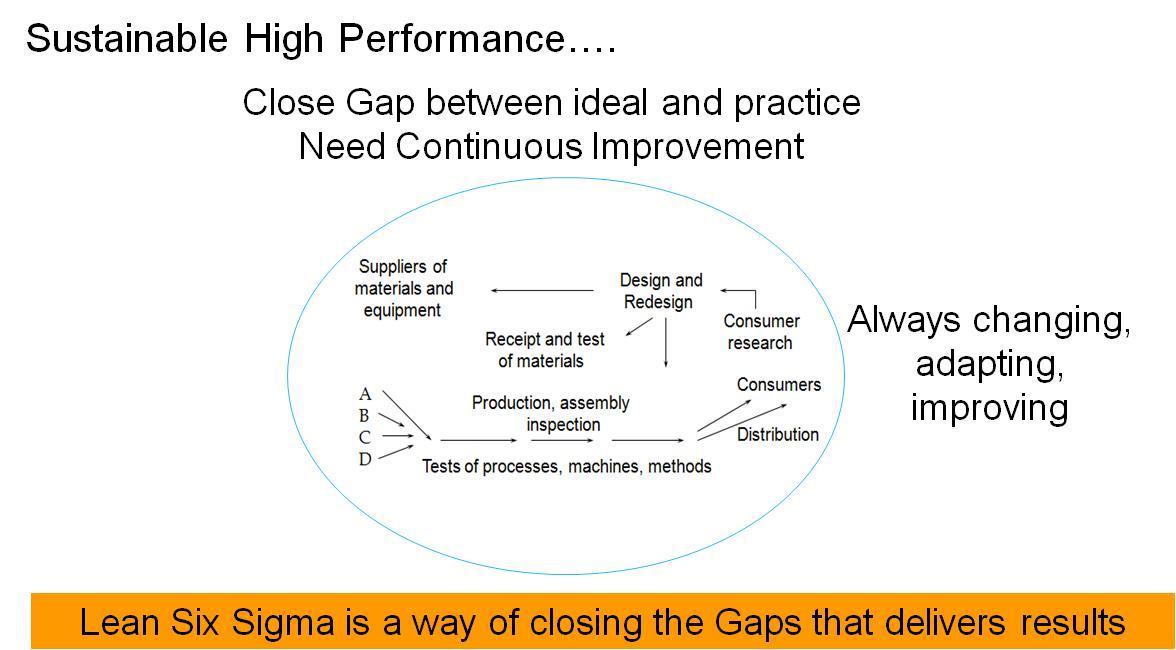

The Gap Between the Ideal and Practice and so Improvement as a CORE Capability

In the complex world of organisations, perfect execution to a design or strategy is unlikely. Many factors influence performance in a Value Stream driving a lack of predictability and dependability and increasing waste and costs. There will always be a gap between the design – the ideal and the current situation. Leaders need to diagnose the critical gaps and apply the talents and energies of the organisation to close the gaps. You cannot fix everything. Random fixes don’t deliver the key shifts for the organisation!! So leaders need to demonstrate strategic learning by hands on governance of improvement – to Lead Organisational Improvement. This process will never go away. The organisation will always be changing, adapting, improving.

It follows that a widespread disciplined approach to closing critical gaps becomes a key competency for all organisations. Here lies the science of improvement. As thinking has evolved in the world of organisational improvement through the application of Deming’s ideas and those of others the concepts and methodologies of Lean Six Sigma has become very popular. Continuous improvement was an imperative for the natural way of operating for any high performance organisation. It had to be part of the DNA for sustainable high performance to emerge. For Deming the valuing of learning and knowledge (Theory of Knowledge principle) and people was key for creating a high performance organisation. For him it was releasing the talents of the working teams in the organisation so that people were not prisoners of their work systems but worked on improving their work systems. This needed a common disciplined approach that all could learn and practice and therefore establish a culture of improvement.

One way of viewing Lean Six Sigma is as a disciplined methodology for improvement that can be developed as a key capability and cultural characteristic of an organisation if it aspires to excellence. Organisational improvement modelled by Lean Six Sigma can be practiced in an organisation at different levels. A more challenging view of Lean Six Sigma would be to see it as a disciplined methodology for bringing about change – a change management methodology. To add a further challenging perspective is to see Lean Six Sigma as a methodology for bringing about change that is a measurable improvement that is sustained. For Deming, this was the contribution of such a continuous improvement methodology – to close the gaps between the ideal and practice in a never ending cycle of learning, change and improvement.

So for Deming Sustainable High Performance is driven by Designing the Value Stream to Fit the Market and then Executing the Design which was very dependent on a vigorous practice of organisational improvement that would drive learning and demonstrated improvement. As learning from improvement emerges of course the design / strategy can be adapted. This is the challenge for leaders in an organisation – to harness capability to create an organisation that can adapt and change in ways that shows measurable improvement that can be sustained.

Feedback from those who attend our programs suggest that organisational improvement is very rarely interpreted in the ways discussed above. Often the methodology is practiced without great flexibility, becomes overly tool driven and highly statistical and in many instances people describe detailed process mapping that can go on for months as the first step to achieving measurable improvement!!

As well, the majority of voices indicate that Leaders are rarely involved and often see improvement work as too operational or tactical and not very strategic. Improvement is left to first line managers and middle managers which often leads to a lack of alignment. Of course the prior condition of having a blueprint based on the exercise of strategic thinking around markets and the design of value streams is absent. Without the clear piece of music that the whole orchestra can follow its very difficult to call out improvements that are significant shifts in the value stream!!

Yes there are tactical improvements to be called out but they lie within the parameters of the strategic changes needed for the organisation. Leaders need to call this out and harness resources and capability to deal with these issues first. This is Leadership work carried out in their weekly and monthly meetings, their planning sessions and their engagement with people within the organisation.

As the drought (e.g.GFC) hits all the rocks come to the surface and the need to sort things out becomes even more imperative.

Whilst this is somewhat poetic of me, in a sense when you wait for the disaster to hit its almost too late. The kind of powerful organisation Deming was calling out was one built over time. It takes time to build a powerful organic engine that can adapt and change to the circumstances around it.

As a result of stories, feedback over time and working with different organisations I titled this ‘outpouring’ “A Paradigm Fading”!

How do you see the current organisational environment in which you operate? Do you see the exercise of Leadership as I have tried to describe it here? What stories do you have about how improvement is handled in your organisation?

It would be good to have a dialogue on the subject so please respond and tell us your experiences.